Convolute Wound

Straight Roll, commonly known as Convolute cores are much more resistant to bending, which their main use as rolls for metal, wire, construction industries. They can be supplied with a large inner diameter from 260mm up to 510mm with wall thickness ranging from 3mm up to 40mm and a maximum length of 1520mm.

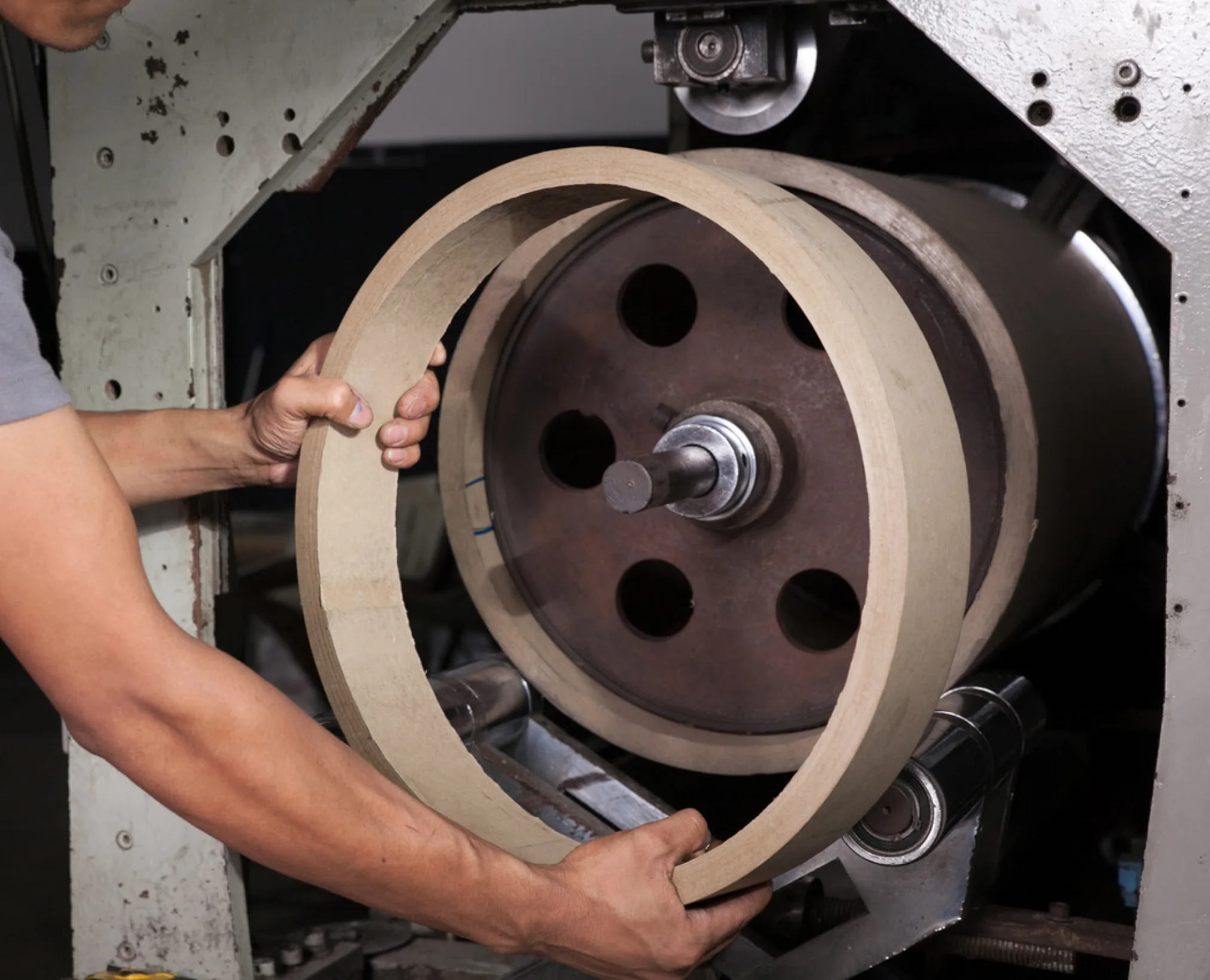

By their nature, convolute cores are more costly to make than spiral cores — convolute cores must be made one roll at a time in fixed lengths, then trimmed to size. Spiral cores are made by continuous processes.